Electronics for the Efficiency of Agricultural Machinery

Find out about the structure and applications of ISOBUS cables in our new white paper.

The reliable transmission of electrical power and data is becoming increasingly important in agricultural technology as more and more equipment features electric drives and sensors. Thanks to the globally standardized ISOBUS system, the use of electronics in agricultural machinery is easier and the efficiency of equipment is greater than ever before. However, in order to avoid errors in communication and power supply, robust and weather-resistant cables are essential. This white paper describes important structural elements of ISOBUS cables and how you, as a user, can benefit from this technology.

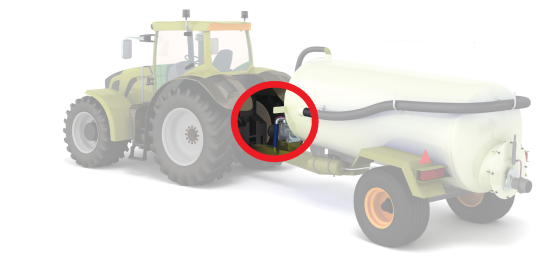

ISOBUS cables in the field

ISOBUS cables are used worldwide in agriculture as a connecting cable between the tractor or a mobile working machine and add-on equipment, also known as implements. They ensure data communication between the machines in addition to supplying power to the control units and working drives. This is why these cables have a hybrid structure. For cabling that transmits information within a machine, other cable types are typically used. These are also based on ISOBUS or CAN bus communication and are sometimes combined with conductors for power supply.

The importance of ISOBUS cables

In the field, ISOBUS cables have to withstand different strenuous conditions. These include fluctuating temperatures, weather and humidity as well as various chemical and mechanical effects such as movement and vibration. Farmers require cable connections that ensure the reliable operation of machines despite all the challenges - after all, malfunctions can result in expensive crop failures, among other things. For this reason, ISOBUS cables are designed to be extremely robust. A special emergency release in the connection socket - the so-called breakaway function - prevents damage to the cable and socket if the plug is removed accidentally. This can happen, for example, if the user forgets to disconnect the cable when parking the tractor equipment.

Proper ISOBUS cable construction is crucial

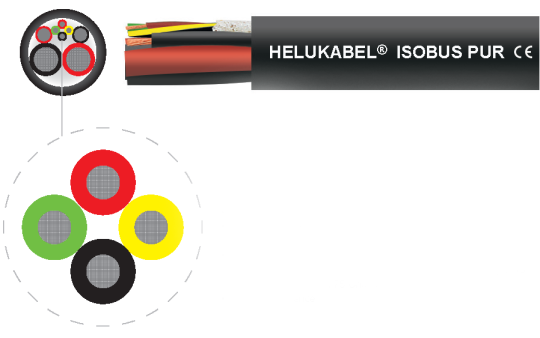

ISOBUS cables are constructed in a so-called star quad formation with 1 x 4 x AWG 20 (0.5 mm²). This structure is crucial for reliable data communication between the machines. The conductor insulation is made of polypropylene (PP) which has good electrical properties that makes it suitable for data transmission applications. Additionally, this insulation material is frequency-stable while complying with the electrical specifications for data transmission. With PVC insulation materials, this is not the case.

Advantages of ISOBUS systems compared to non-ISOBUS machines

In the past, different types of add-on equipment also meant several control units in the tractor cab as well as different cables and plug connectors. This made work unnecessarily complicated for farmers, and, even more, individual units could not be replaced due to a lack of compatibility. The globally standardized ISOBUS system solves this problem by providing a uniform cable connection for data communication between agricultural machines. As a result, users can easily and conveniently attach different types of add-on equipment, operate them from the tractor with the same terminal and make adjustments while driving. Farmers can therefore respond much more precisely to individual soil conditions and other needs, as well as dose fertilizers and other chemical substances more accurately. This improves the quality of work and therefore boosts yields. At the same time, the soil and groundwater are protected and operating costs are reduced. In this way, ISOBUS makes a holistic contribution to greater efficiency in agriculture. The technology makes the farmer’s daily work easier and reduces workload. Data obtained during the daily work can be evaluated and provide a transparent overview of an agricultural operation.

ISOBUS Cable Construction

The properties and structure of the star quad formation are regulatedin the ISO 11783-2 standard. This defines the following parameters, among others:

- Conductor colors

- Conductor sequence within conductor stranding

- Stranding lay length

- Impedance of wire pairs (green/yellow or red/black 20 Ohm +/-10% @1MHz)

- Impedance between the pairs and touching conductors (red/black pair measured to green or yellow conductor or green/yellow pair to red or black conductor: 75 Ohm +/-5 Ohm @1MHz)

- Mutual capacitance

What do the conductor colors mean?

| CAN High | CAN Low | TBC Power | TBC Return |

Why Choose ISOBUS Cables?

When Applications Require:

- Robust cable construction

- Damage-free breakaway function

- Reliable data transmission at any time

- For use in various weather conditions and fluctuating temperatures

- Reliable function despite external mechanical and chemical effects

- High current carrying capacity for more powerful equipment

- Cable that is easy to work with

ISOBUS PUR Advantages:

- PP conductor insulation in star quad for reliable data transmission according to ISO 11783-2

- Robust TPU jacket, wear and abrasion resistant

- Outer jacket diameters compatible with the requirements of the common connector types

- Resistant against: weather conditions, UV-rays, microbes, ammonia

- Oil resistant acc. to DIN VDE 0473-811-404 / DIN EN 60811-404 / IEC 60811-404

- Mud resistance acc. to IEC 61892-Annex D

- Flame retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

- High-pressure cleaning possible (temperature, exposure time and water pressure dependent)

- Outer jacket is easy to strip and is excellent for adhering to overmolded assemblies.

ARTICLE DOWNLOAD

Click here to view this article in our digital download center.