Robotic Electrical Connection Technology, Guidance & Protection Systems

In the industrial automation sector, robotics are at the forefront of innovation, allowing companies to enhance efficiency and safety to reshape the manufacturing and production landscapes. Sophisticated robotic systems have enabled unparalleled levels of precision and consistency in applications such as spot, laser, and inert gas welding, material handling, and tool-changing systems. With their ability to execute intricate tasks with repetitive accuracy, robots are now indispensable in industries requiring meticulous attention to detail, from electronics assembly to automotive manufacturing.

The 3D motion sequences of an industrial robot are only as good as the cables that transmit power and data, as well as the guidance and protection systems that prevent these pivotal components from being interfered with by environmental hazards. HELUKABEL has over 25 years of experience developing electrical system solutions for the robotics field.

With its abilities to be able to supply robotic torsion-resistant cables, dress packs and drag chains for robots that need to travel laterally, HELUKABEL is able to adapt and respond more rapidly and efficiently to evolving customer demands in dynamic markets.

Take a look at our solution capabilites for the robotic automation ecosystem or directly on the robot .

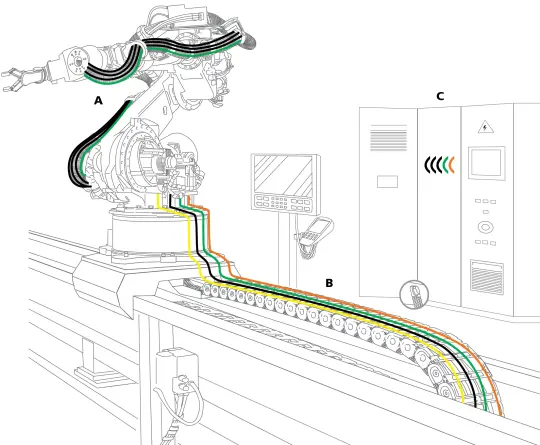

Robotic Automation Ecosystem

Application

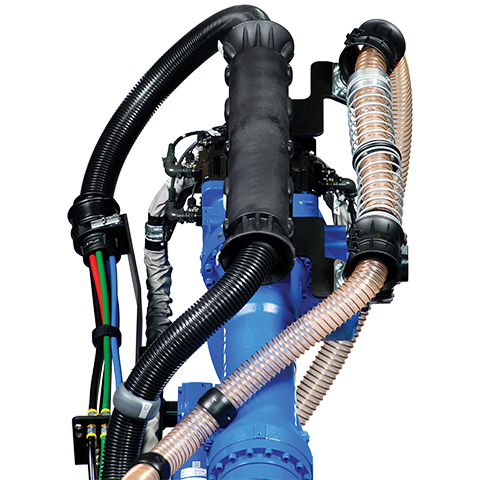

- Robotic Dress Packs

- Drag Chain - Axis 7

- Control Panel/Cabinet

HELUKABEL Solutions

| A - Robotic Dress Packs HELUCONTROL® ROBOFLEX®-D HELUDATA® ROBOFLEX®-PAIR-D HELUPOWER® ROBOFLEX® HELUKAT® 100 T Tordierflex HELUKAT® PROFINET Type R HELUKAT® 600 S PROFINET Torsion, SF/FTP, Cat. 7 HELUcond PA12 Corrugated Tube | B - Drag Chain - Axis 7 TOPSERV® 109/113/121 PUR TOPGEBER 512 PUR TOPSERV® Hybrid PUR ROBOFLEX®-recycle MULTISPEED® 500-PUR UL/CSA MULTIFLEX 600 MULTIFLEX 512®-PUR UL/CSA SUPER-PAAR-TRONIC 340-C PUR HELUKAT® PROFINET Type C | C - Control Panel/Cabinet H07V-K / 07V-K FIVENORM HELUKAT® PROFINET Type A or B M12 & RJ45 Automation Cordsets HELUTOP® Cable Glands Copper Grounding Strap |

The product families listed above are a consolidated overview and not our comprehensive portfolio of available solutions. For more information on our electrical system solutions for robotics, please contact us.

Robot Power & Control

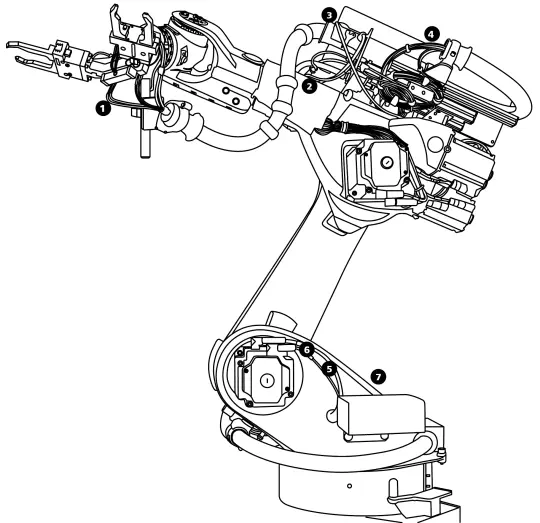

Cables and wires from HELUKABEL have many different purposes in robotics. They can transmit power, data and control signals – in some cases, all three at once. For robots to reliably perform every movement, the cables installed must have an appropriate design, e.g. torsion resistance if used in the dress pack or continuous flex if used within the robot’s drive/control system, and be made of the appropriate materials.

HELUKABEL Solutions

| 1 - Sensor cables such as HELUDATA® ROBOFLEX®-RECYCLE PUR UL/CSA transmit signals from the sensors fitted on the robot to the respective receiver. This is used for position detection as well as for displacement and force measurement, for example. | 5 - Servo cables such as TOPSERV® 109 PUR supply power to the numerous servomotors on the various axes of the robot. Additionally, the tools fitted to the robot’s arm are set in motion by these motors. |

| 2 - Data cables such as PROFINET Type R transmit a wide variety of information from the robot to the external systems – from sensor data to camera images and videos. Seamless data transmission is required for production and condition monitoring as well as for a smart production network. | 6 - Feedback cables such as TOPGEBER® 512 PUR are used to control the servomotors. The electrical signals specify how far, at what speed, and in what direction a robot axis moves, for example. |

| 3 - Control cables such as HELUCONTROL® ROBOFLEX®-D PUR UL/CSA transmit signals that control individual components on the robot. When connected to a controller, you can instruct a gripper to open or close, for example. | 7 - Ground conductors such as the SINGLE 602-RC-J are used for grounding the robot. They protect the equipment and the operator against current leakage and electric discharge. |

| 4 - Power cables such as a robot’s PRIMARY CABLE have high torsion resistance and flexing capabilities that makes them suited for providing power to the EOAT in extreme automated applications such as welding and material handling. |

The product families listed above are a consolidated overview and not our comprehensive portfolio of available solutions. For more information on our electrical system solutions for robotics, please contact us.